- Your cart is empty Browse Shop

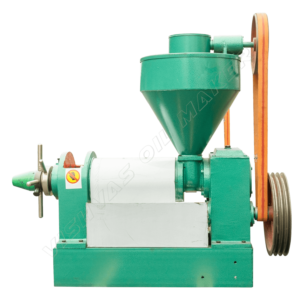

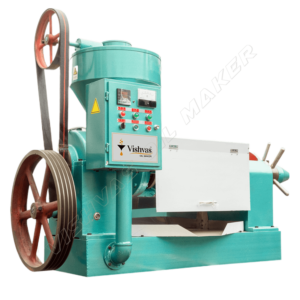

- Sale! All Products, Commercial Oil Press Machine

Commercial Oil Press Machine | Automatic Oil Press Machine VI-1300(B)

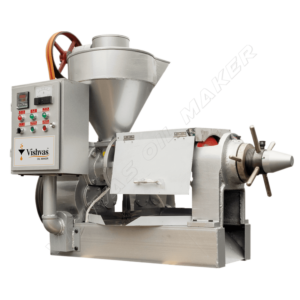

₹230,100₹260,100(Including 18% GST) - Sale! All Products, Commercial Oil Press Machine

Commercial Oil Press Machine | Cold Oil Press Machine Commercial VI-3000(A)

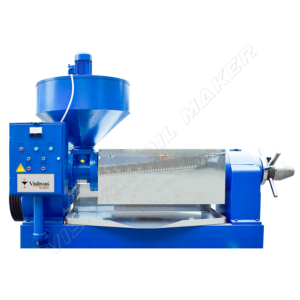

₹370,520₹420,000(Including 18% GST) - Sale! All Products, Commercial Oil Press Machine

Commercial Oil Press Machine | Cold Press Oil Machine Commercial VI-20000(A)

₹1,829,000₹1,979,000(Including 18% GST) - Sale! All Products, Commercial Oil Press Machine

Commercial Oil Press Machine | Commercial Oil Press Machine India VI-6500

₹828,300₹928,300(Including 18% GST) - Sale! All Products, Commercial Oil Press Machine

Commercial Oil Press Machine | Cooking Oil Commercial Press Machine VI-3000(B)

₹295,000₹345,000(Including 18% GST) - Sale! All Products, Commercial Oil Press Machine

Commercial Oil Press Machine | Mini Oil Mill Machine VI-10000

₹1,062,000₹1,212,000(Including 18% GST) - Sale! All Products, Commercial Oil Press Machine

Commercial Oil Press Machine | Oil Extraction Machine Commercial VI-6500(B)

₹556,960₹656,960(Including 18% GST) - Sale! All Products, Commercial Oil Press Machine

Commercial Oil Press Machine | Oil Making Machine for Business VI-10000(A)

₹952,260₹1,102,260(Including 18% GST) - Sale! All Products, Commercial Oil Press Machine

Commercial Oil Press Machine | Oil Press Machine Commercial VI-10000(B)

₹808,300₹958,300(Including 18% GST) - Sale! All Products, Commercial Oil Press Machine

Commercial Oil Press Machine | Oil Press Machine for Commercial Use VI-6500(A)

₹654,900₹753,900(Including 18% GST) - Sale! All Products, Mini Commercial Oil Press Machine

Mini Commercial Oil Press Machine | Mini Commercial Oil Expeller Machine VI-660

₹99,500₹115,000(Including 18% GST)

An oil expeller machine, also known as an oil press or oil extraction machine, is a mechanical device used to extract oil from various oil-bearing seeds or nuts. It works on the principle of mechanical pressing, where the seeds are fed into the machine’s chamber, and a screw mechanism applies pressure to crush the seeds and extract the oil.

Here’s a simplified breakdown of how an oil expeller machine typically works:

Seed Feeding: Seeds or nuts are fed into the machine’s chamber through a hopper.

Pressing Mechanism: Inside the chamber, there’s a screw or worm shaft that rotates and pushes the seeds against a pressing cage or barrel.

Pressure Application: As the seeds are pushed through the barrel, they experience increasing pressure, which causes the oil to be squeezed out of the seeds.

Oil Extraction: The expelled oil flows out through small openings or perforations in the pressing cage or barrel, while the residue, known as oil cake or meal, is pushed out separately.

Oil Filtration: Depending on the design, some oil expeller machines may have built-in filtration systems to separate impurities from the extracted oil.

Collection: The extracted oil is collected in containers for further processing, while the oil cake can be used as animal feed or processed into other products.

Oil expeller machines come in various sizes and capacities, ranging from small household models to large industrial ones capable of processing tons of seeds per day. They are commonly used in the production of edible oils such as soybean oil, sunflower oil, peanut oil, and sesame oil, among others. Additionally, they are also utilized in the extraction of non-edible oils for industrial purposes, such as biofuels or essential oils.