Collection: Products

-

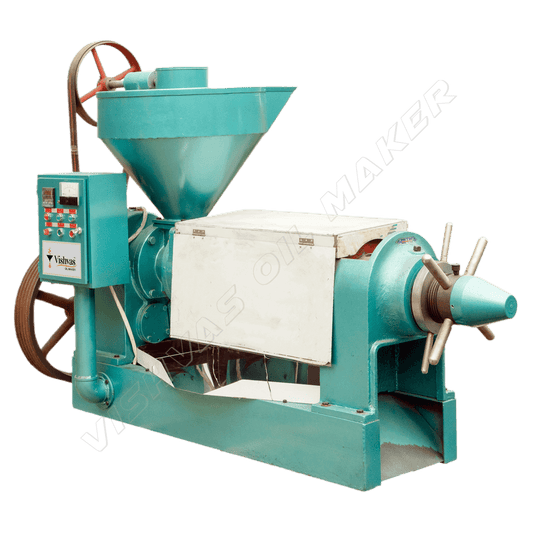

VI-6500(A)1 review

Commercial Oil Press Machine | Oil Press Machine for Commercial Use VI-6500(A)

Regular price ₹654,900Sale price ₹654,900 Regular priceUnit price / per₹753,900(Including 18% GST)(Including 18% GST)Sale -

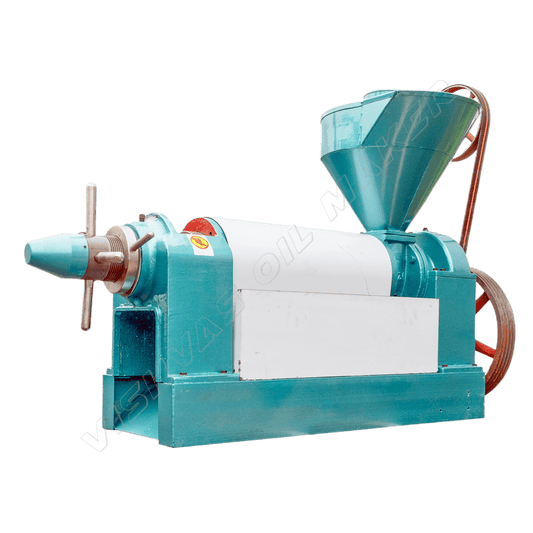

VI-10000(B)1 review

Commercial Oil Press Machine | Oil Press Machine Commercial VI-10000(B)

Regular price ₹808,300Sale price ₹808,300 Regular priceUnit price / per₹958,300(Including 18% GST)(Including 18% GST)Sale -

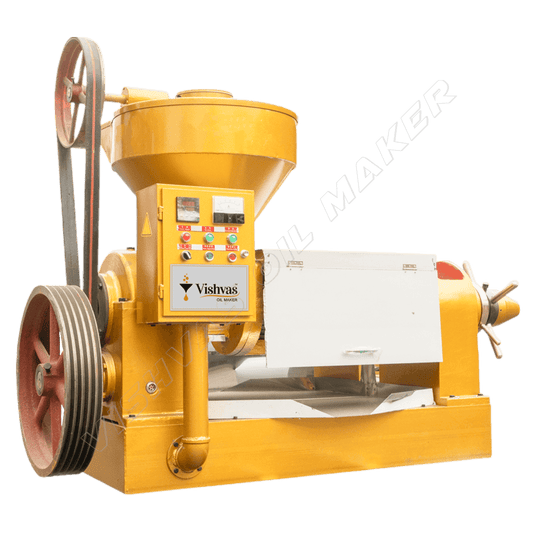

VI-10000(A)2 reviews

Commercial Oil Press Machine | Oil Making Machine for Business VI-10000(A)

Regular price ₹952,260Sale price ₹952,260 Regular priceUnit price / per₹1,102,260(Including 18% GST)(Including 18% GST)Sale -

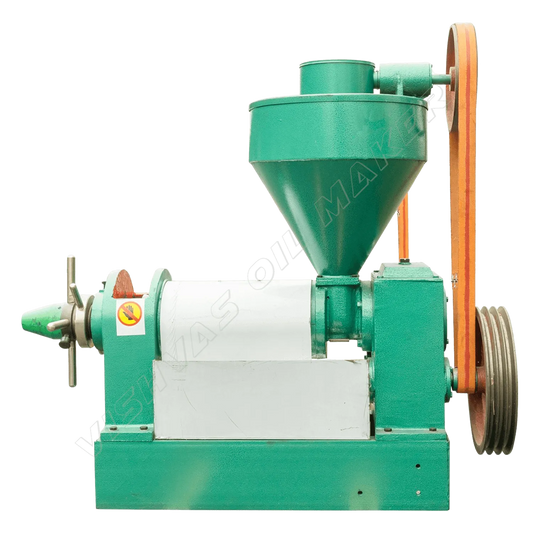

VI-6500(B)1 review

Commercial Oil Press Machine | Oil Extraction Machine Commercial VI-6500(B)

Regular price ₹556,960Sale price ₹556,960 Regular priceUnit price / per₹656,960(Including 18% GST)(Including 18% GST)Sale -

VI-100001 review

Commercial Oil Press Machine | Mini Oil Mill Machine VI-10000

Regular price ₹1,062,000Sale price ₹1,062,000 Regular priceUnit price / per₹1,212,000(Including 18% GST)(Including 18% GST)Sale -

VI-3000(A)3 reviews

Commercial Oil Press Machine | Cold Oil Press Machine Commercial VI-3000(A)

Regular price ₹370,520Sale price ₹370,520 Regular priceUnit price / per₹420,000(Including 18% GST)(Including 18% GST)Sale -

VI-1300(B)1 review

Commercial Oil Press Machine | Automatic Oil Press Machine VI-1300(B)

Regular price ₹230,100Sale price ₹230,100 Regular priceUnit price / per₹260,100(Including 18% GST)(Including 18% GST)Sale

An ideal commercial oil press machine balances reliability, efficiency, build quality, and consistent performance. A well-made machine uses durable, food-grade stainless steel or heavy-duty metal parts and features a strong screw-press mechanism for continuous operation. It should be capable of handling a variety of oilseeds — such as groundnut, sesame, mustard, sunflower, coconut, soybean — giving flexibility in the types of oils you produce. Automatic or semi-automatic versions help reduce manual labour by managing seed feeding, pressing, temperature control and filtration, which improves throughput while maintaining oil purity and nutritional quality.

For businesses that need stable daily output, a mid-capacity machine with good build quality and sufficient motor power delivers steady oil yield. For small shops or start-ups, a compact machine that still uses efficient pressing technology and food-grade materials can offer a cost-effective way to begin producing edible oil. Ease of cleaning and maintenance is important for hygiene and long-term reliability, while energy efficiency helps reduce ongoing operating costs.

Whether you run a small shop, an organic-oil business, a mini oil mill or a medium-scale production unit, the best commercial oil press machine will deliver clean, chemical-free oil, handle different seeds efficiently, operate smoothly with minimal supervision, and require manageable investment and maintenance.